WE MANUFACTURE

MOULDS

THAT TURN

YOUR IDEAS INTO REALITY

We manufacture injection molds and plastic injection parts. We inject your products very quickly, whatever the quantity!

Are you looking for a partner to manufacture small or large series of injection-molded parts?

LEARN MOREAre you paying too much for your injection molds?

We have compared prices with several suppliers in several countries.

We deliver prototypes to your premises in less than a week. We make injection molds in 5 working weeks; we usually deliver the first injected parts in 7 weeks.

At a time of digital transformation and exploration of new markets, time-to-market has never been more important, or more critical. In this context, rapid injection molding is particularly well suited to on-demand production, transition tooling, pilot series and, of course, functional prototyping.

- It's choosing a European company

Today, taking over a Belgian plastics manufacturer (plastic injection mold munfacturing) means taking the side of Plastic Europe relocation. It is therefore above all a strategic decision for every entrepreneur, going well beyond ecological and environmental considerations by recovering waste and recyclable materials: a far-sighted manager also protects himself from a legal point of view, and ensures his sources of supply, even if it means diversifying them at the level of his choice. This is a wise choice, all the more so as it will be made at the same quality/price ratio, thanks to a controlled cost policy.

- It means selecting a company with know-how

With 30 years of experience, Moulding Injection (cheap injection mould – Manufacture of injection moulds) has the technical expertise to anticipate problems and propose solutions upstream, right from the design phase.

This saves time and money.

These answers are all the more concrete, as they are accompanied by a perfect knowledge of the European market, both as professionals and consumers that we are. We therefore include both an industrial and a marketing vision in this approach, as in a product market fit approach.

- It means working with passionate people

Relocating a plastic injection production is by definition geographically closer. But it is in fact much more than that, it is recreating a bond of proximity.

Because if Moulding Injection practices a very technical activity, at the cutting edge of technology, it nevertheless places the human being at the heart of its process, by listening to its customers, by dialoguing, exchanging, anticipating the reactions of the final customer...

By being close to you, we are not looking to sign a one shot contract, we are above all looking for your permanent satisfaction, for a long term collaboration.

Do you think that Chinese customer service or commercial service is far away? It is normal!

On the contrary, Moulding Injection is close to you, to your desires, to your factories, to your distribution points.

Thermoplastic injection moulding is a production process that enables the mass production of identical plastic parts with an injection moulding press. The plastic is first softened through heating and then injected into a mould where it cools down to the desired shape. This method is suitable for very large series (such as car parts) but also for smaller batches (such as packaging for Belgian pralines).

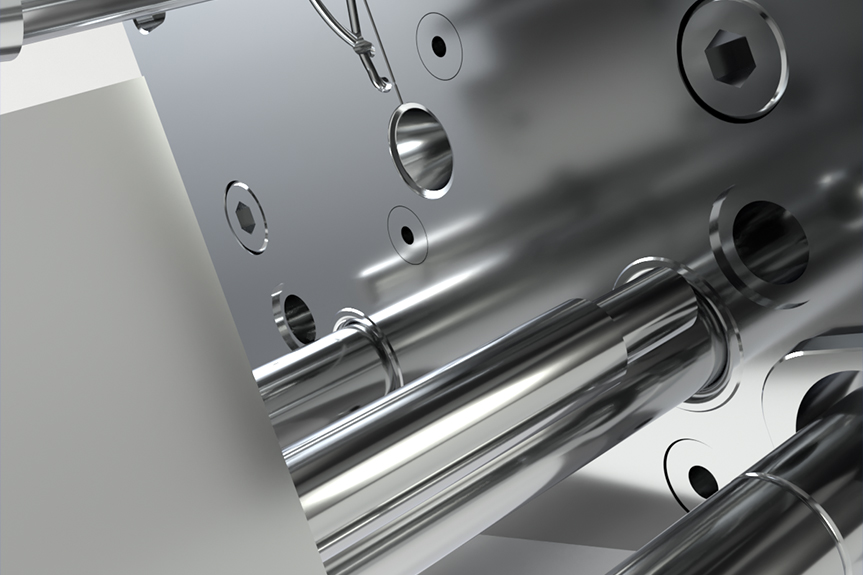

This economical and efficient process uses an injection moulding press, consisting essentially of two parts: the injection unit and the press unit.

The moulds used in the injection moulding press can be positioned horizontally (most common) or vertically (enabling the use of gravity during the manufacturing process).

A cold runner or a hot runner can be used to move the plastic during the injection moulding process.

With a cold runner, the plastic that is used as a guide cools, hardens and is ejected together with the piece. When using a hot runner, the channel remains hot and the plastic runner inside can be used for the next piece, without being ejected.

As a true professional of precision injection moulding in Europe, Moulding Injection chooses the technique that is best suited to its customer's needs thus achieving an affordable injection mould that delivers flawless end products. A good mold guarantees a good plastic product.

Equipped with a suitable and interchangeable plastic mould, the injection moulding press is first filled with raw materials, usually plastic granulate.

A screw moves these polymers forward while the plastic is heated through friction and turns into a liquid substance. The screw gradually generates pressure. As soon as the desired pressure is reached, the liquid is injected into the injection moulds that are located in the closing units.

A good injection moulder chooses its plastic, based on its customer needs. Moulding Injection works with quality polymers for a large production of plastic parts. Silicone casting, on the other hand, is better suited for small series.

There are different types of presses to make plastic injection moulds. Hydraulic injection moulding machines are the oldest and most widely used in Asia. However, they do not allow precision casting. With a mechanical injection moulding machine, the closing mechanism is ensured by toggle switches. A large tonnage is required because "flash" may appear on the plastic if the closing mechanism opens, causing it to lose its mechanical properties.

Moulding Injection therefore selected high-quality presses, both electric and hybrid types, to ensure a high-quality production of plastics in Belgium.

Injection moulding machines can be more or less automated. Some are manually filled with granulate. Moulding Injection has opted for the latest generation of presses, with maximum automation, enabling 24-hour production. This strategic decision offers excellent value for money and is competitive with Chinese alternatives. (Affordable injection moulding and discount for plastic production in Belgium)

Choosing a precision injection moulding process in Europe requires ultimate quality machinery with optimal performance. This is a reasonable expectation of customers choosing to relocate their plastic production without an increase of costs.

Thanks to our know-how, Moulding Injection can create a large number of parts through plastic moulding and is able to meet every functional demand in France, Belgium and the rest of Europe: transparent polycarbonate lids, colored magnetic beads, luxury packaging boxes for Belgian chocolates, promotional pill boxes for pharmacies, original trendy frisbees for toy shops, ABS cubes for liquor stores, adults toys...

Whether large series or small volumes, Moulding Injection can meet the specific needs of any professional in any industry. The relocation of your plastic production to Belgium enables our teams to obtain an excellent knowledge of market expectations in both B2B and B2C. In the specific case of promotional items, such as goodies, a relocation to Europe reinforces your company’s image with your customers or prospects.

To guarantee a high quality production, Moulding injection pays a lot of attention to different finishing types:

- industrial polishing of surfaces, followed by sanding or mirror polishing is possible

- marking with raised or recessed relief, to develop a logo or marking on a plastic part

- choice of colors, taking UV durability into consideration

It is therefore possible to respond very well to our customer requests, for a tailor-made product matching their image.

The development of the mould is probably the most technical part of the process, as the design must be perfect for a quality production.

Moulding Injection's philosophy is to combine speed (4-6 weeks on average) with perfection.

In general, a steel mould consists of two parts: one is fixed on the plate, the other one is mobile. A good plastic injection mould guarantees:

- a full and regular filling, so as not to have holes before the cooling begins; each mould type also requires the right injection moulding speed.

- easy dismantling, fast and without stains

During the process of injection moulding, it may be necessary to heat certain parts or cool others to ensure the part's thermal balance.

The layout of the parts is well considered from the start to avoid the presence of defects (cracks, shrinkage, porosity, etc.): the art of the professional mould maker therefore consists of optimizing and enhancing the locations of the injection nozzles for liquid plastic, seams, traces of the ejected parts, remnants...

Needless to say, this specialized work requires an investment but this is compensated by savings during the production phase: less waste, fewer defaults and fewer external operations thanks to precise injection moulding...

Taking into account the global costs (price of plastic injection moulds) makes Moulding Injection perfectly competitive for an ultimately efficient end product exceptional quality, far above the usual Asian standards.

Each customer has specific requirements and expectations for the production of its plastic parts. Moulding Injection's job is to reconcile these requirements as good as possible with the technical limitations.

The design of a plastic part is inseparable from the development of the plastic mould. It forces us to carefully consider all aspects from the production to the final product.

Thus, the mould maker must take into account the limitations specific to the plastic industry, such as the need to have constant thicknesses and the end use of the finished product. If a plastic part is too thick, it can be too heavy, risking cracking and warping, or extending the production time, resulting in an increase of costs. On the other hand, a piece that is too thin may break or may not be strong enough.

It is up to the mould maker to optimize the part. For this, Moulding Injection works with powerful software to determine the best solution in function of the desired price-quality ratio at all times.

In addition to some mechanical limitations, a good design of a plastic product also includes an analysis of the aesthetics, the ease of dismantling and the finishing level of the surface.

- good radiation of the edges ensures a better flow of the plastic in the mould, as well as a better dismantling with less risk of breaking the piece.

- careful design of the remnants ensures that scratches on the plastic are reduced during its dismantling. Moulding Injection thus optimizes the angle of the remains according to the desired finish.

- avoiding drag tracks for a perfect release, or coming up with another technical solution, such as incorporating lateral ribs in the mould.

To reconcile such contradictory limitations, a good injection moulder like Moulding Injection masters various technical skills: designing ledges, deleting ribs, optimizing assembly, using symmetry to cut costs, overmoulding, etc.

A finished plastic part always seems very simple, while the design is often very complex. Moulding Injection masters these techniques in the design phase by combining knowledge and know-how.

Realization of plans, injection moulds in ABS, soft touch finish.

Relocalisation de votre production plastique en Europe ?

Bioplastics are an alternative to thermoplastic materials from the fossil industry. Composed of vegetable…

Patented since 1872, plastic injection molding became widely available in the late 1940s. Today it is…