By ADMIN

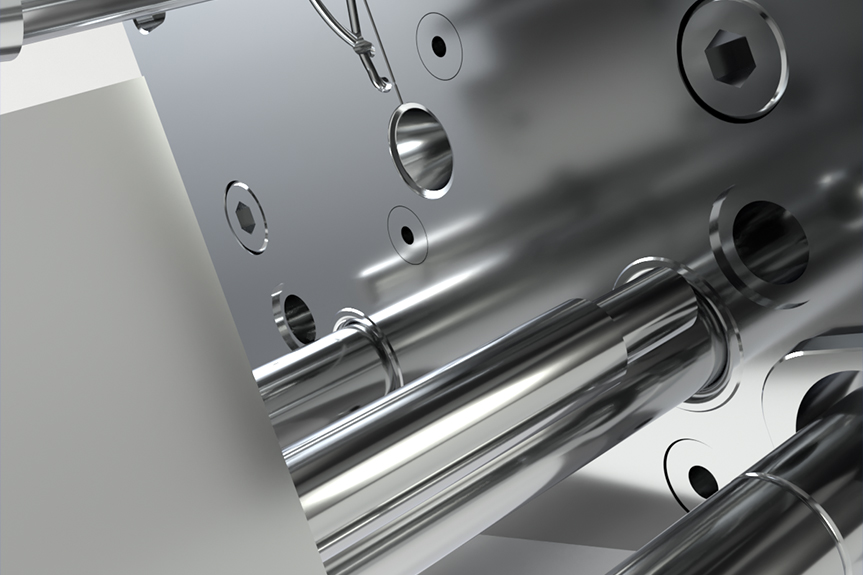

Patented since 1872, plastic injection molding became widely available in the late 1940s. Today it is a notable technology to manufacture certain parts. However, plastic injection molding comes at a price, especially with parts that are produced in series. Thanks to our partnership and payment facilities, the price of plastic injection molding no longer puts a limit on your realizations.

Buy various parts at a lower price

Unique about plastic injection molding is that it enables to manufacture parts that are technically and aesthetically very diverse. However, the final appearance of these parts often depends on how they are designed and also on the constraints of production. This requires a perfect knowledge of the plastic mold operation and the different criteria that influence the quality of a part. It is therefore important to take these criteria into account upstream and minimize error margins. The best way to achieve success in plastic injection molding is to involve the injection molding company at all stages of the development process of plastic parts. In addition to guiding your thinking process, we have very affordable prices that facilitate our cooperation. We currently allow payment for the tools for your injection molds to be spread over a year. In addition, we can participate up to 50% in the price of your product.

Plastic injection molding: remarkably efficient

This technology is also called thermoplastic injection and is distinguished by its efficiency. It is the most expensive and slowest technology for rapid prototyping but perhaps the most efficient in terms of results. It enables you to make prototype parts of very good quality. These retain the same mechanical and strength properties. The industrialization specifications are the same as the production parts because the manufacturing process is the same. Our advantage is that we can offer you a sustained production speed and a much lower unit cost price. When we know that making a mold is the only significant investment, we offer the option for co-creation of and co-investment for the mold.

Realization of plans, injection moulds in ABS, soft touch finish.

Relocalisation de votre production plastique en Europe ?

Bioplastics are an alternative to thermoplastic materials from the fossil industry. Composed of vegetable…

Thermoplastic injection moulds enable mass production of functional objects. The process is applied…