By ADMIN

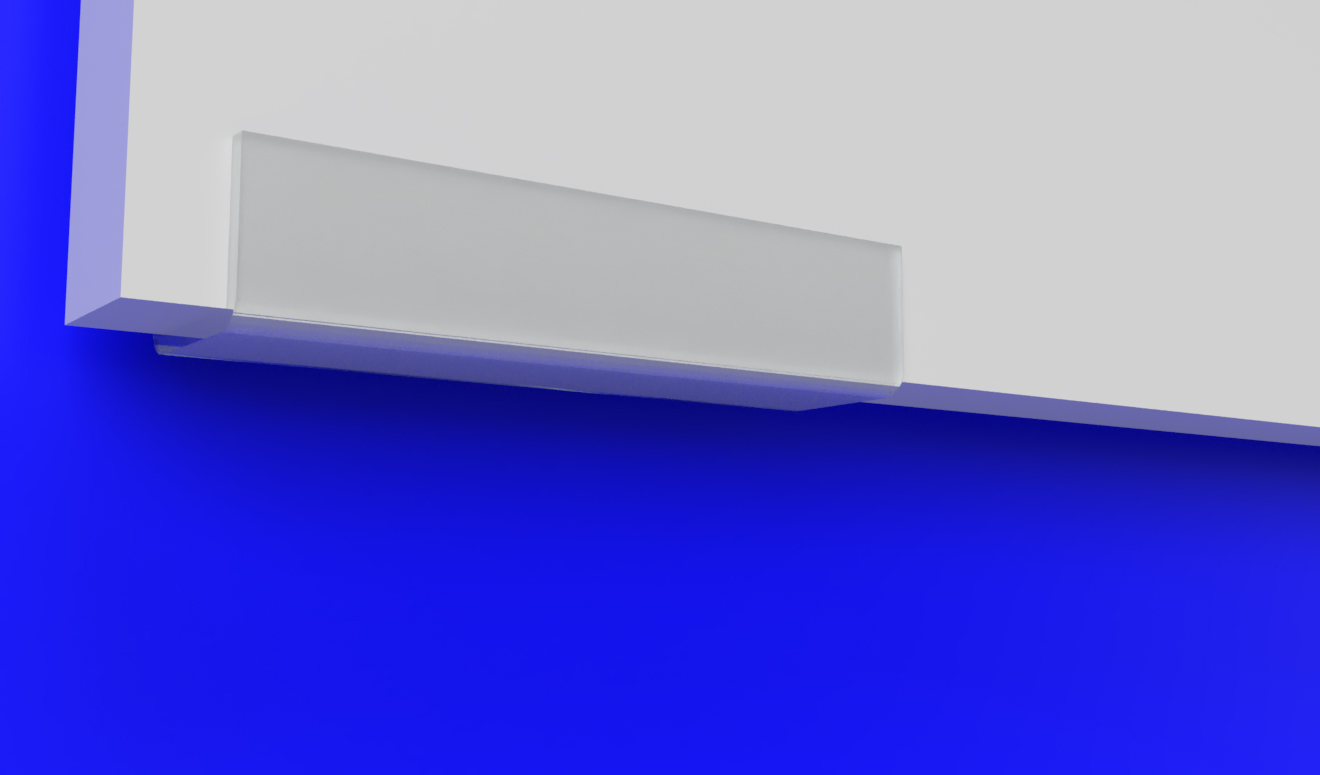

How did we go about it? We produced the tooling, i.e. the steel mold, in 6 weeks. The first samples of the display unit were then delivered to Julien for testing. After a few adjustments to the dimensions, the product was born.

We chose polycarbonate for its production, as this plastic material is light yet has excellent resistance. MusiWall customers will have an easy-to-handle, rigid and transparent display that fits in with any style of home!

As a manufacturer of plastic injection molds, we help projects like MusiWall to develop their ideas and prototypes into high-quality finished products. Whether production runs are small or large, we offer to co-create the project, with involvement at every stage of the process: contact, tooling, design adjustment, plastic injection and packaging.

We also believe that quality and value go hand in hand. At Moulding Injection, you'll find a solid partnership where listening and constant exchange will enable us to meet your most specific plastic injection molding needs. All at a democratic price!

How did we go about it? We produced the tooling, i.e. the steel mold, in 6 weeks. The first samples of the display unit were then delivered to Julien for testing. After a few adjustments to the dimensions, the product was born.

We chose polycarbonate for its production, as this plastic material is light yet has excellent resistance. MusiWall customers will have an easy-to-handle, rigid and transparent display that fits in with any style of home!

As a manufacturer of plastic injection molds, we help projects like MusiWall to develop their ideas and prototypes into high-quality finished products. Whether production runs are small or large, we offer to co-create the project, with involvement at every stage of the process: contact, tooling, design adjustment, plastic injection and packaging.

We also believe that quality and value go hand in hand. At Moulding Injection, you'll find a solid partnership where listening and constant exchange will enable us to meet your most specific plastic injection molding needs. All at a democratic price!

The fluidity between design and production is at the heart of our partnership with LGR Design Studio.…

Do you have a plastic part without its original blueprint? Do you need to improve a design or restart…

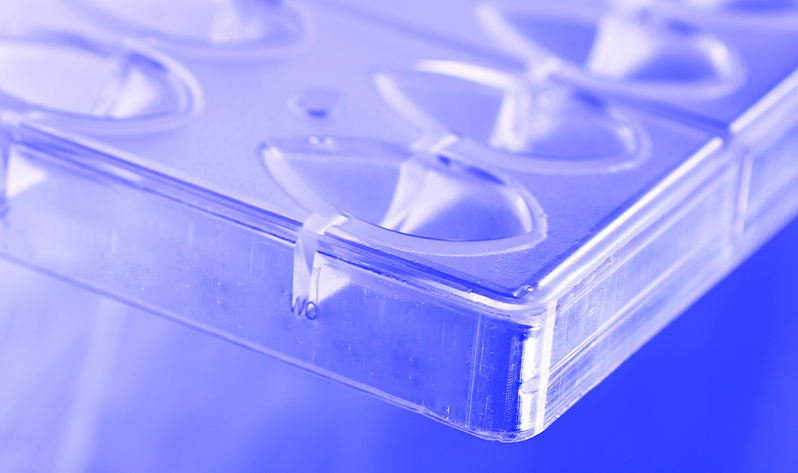

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…