Are you looking for a plastic injection mold manufacturer?At a time of digital transformation and exploration of new markets, time-to-market has never been more important, or more critical. In this context, rapid injection molding is particularly well suited to on-demand production, transition tooling, pilot series and, of course, functional prototyping. As a designer and marketer, Olivier Vereecken is with you every step of the way. From initial brainstorming to production follow-up, Olivier and…

Manufacturing the injection mold is a crucial step in the process of producing plastic injection-molded parts, and the key to realizing your project.As you know, mold making is expensive! That's exactly where Moulding Injection sets itself apart. (both in Belgium and in France).We've invested in high-performance, high-speed machinery, so we can offer you unbeatable prices on the manufacture of your injection mold.Our average manufacturing time for plastic injection molds is 5-8 weeks. We…

Best Injection Molding Company in Belgium – Fast, Reliable & AffordableLooking for a reliable and affordable injection molding solution in Belgium? Whether you need rapid prototyping, low-volume manufacturing, or high-volume plastic part production, Moulding Injection is your trusted partner. As the best injection molding company serving the Belgian market, we specialize in delivering high-quality, precision-molded plastic components at unbeatable prices.We combine modern injection molding…

Expertise in Small Automotive Technical PartsIn modern automotive engineering, reliability is found in the details. Moving away from the race for size, we specialize in the injection molding of **precision components, connectors, and functional supports**.Our infrastructure is scaled to produce small to medium-sized parts (from a few millimeters up to 20-30 cm), where tolerances are measured in hundredths and material quality is critical for the safety and durability of on-board systems.1. Geometric…

Precision at the Service of HealthcareIn the medical and paramedical sectors, a plastic part is not just a simple component: it is often the guarantor of a device’s seal or a patient’s safety.Our expertise focuses exclusively on the injection molding of small technical parts and tubular geometries. We support medical device manufacturers and laboratories in the production of components requiring absolute finesse and cleanliness.1. “Tubular” and Connectivity ExpertiseThe injection…

The Alliance of Fine Engineering and DesignIn the high-end lighting sector, plastic must not only be functional, it must be beautiful. We produce trim and fastening components that meet the dual requirements of both designers and installers.Our specialty? Revolution parts (rings, flanges, diffusers) integrating high-precision threading and uncompromising surface finishes.1. Mastery of "Fine Pitch Threads" and UnscrewingSuccessfully molding a plastic thread on a thin ring is a technical…

Silicone: Flexibility, Resistance, and BiocompatibilityWhen conventional thermoplastics reach their limits in terms of thermal resistance or flexibility, silicone is the answer. We master two distinct processes to meet all your needs, from single prototypes to mass production.1. Liquid Silicone Rubber Injection (LSR)For serial production, high precision, and medical applications.LSR (Liquid Silicone Rubber) injection is an industrial process using specialized presses to inject a two-component system…

The Art of Imitation: High-Density PolyurethaneIn interior design and architecture, the weight and cost of natural materials (solid wood, hewn stone, traditional plaster) are often major obstacles. Polyurethane (PU) offers the perfect solution: a complete visual illusion combined with unparalleled ease of installation.We produce structural or decorative elements using the injection or casting of rigid PU foams, capable of reproducing the finest texture details.1. Perfect Imitation of Fine MaterialsThanks…

Injection mold manufacturing is the centerpiece of your project. It is often the longest and most expensive stage. At Moulding Injection, we have chosen to make a difference exactly on this point: reducing lead times without exploding the budget.Our Commitment: 5 to 8 WeeksThanks to our high-performance machinery and our organization in Belgium, our average mold manufacturing time is 5 to 8 weeks. Where others take months, we ensure high-precision machining within tight deadlines.Why are we faster…

In a world of dwindling resources, the plastics industry is often singled out. At Moulding Injection, we refuse to accept this as a finality. We are convinced that plastic—when well-designed, durable, and recycled—remains an essential material for the future.Our commitment to eco-responsibility is more than just a label. It is a profound transformation of our working methods, built on four fundamental pillars.1. Eco-Design: Thinking about End-of-Life from the StartResponsibility begins…

Are you facing a stock shortage? Is your supplier telling you the part is "obsolete"? Or worse: are they offering a simple plastic part at an exorbitant price?Stop paying a premium just for a brand name.At Moulding Injection, our specialty is simple: if you have the part (even if it's broken), we can reproduce it identically—often at a lower cost than the official manufacturer.The Problem: The Spare Parts MonopolyIn both the industrial and automotive sectors, manufacturers make…

The gap between "Design" and "Factory" is the #1 cause of industrial project failure. We have eliminated it. Too many projects (Startups, IoT, Medical) waste months going back and forth between an external design bureau (unaware of machine constraints) and a mold maker. At Moulding Injection, we have integrated engineering directly into the factory heart through our exclusive partner, LGR Design Studio.1. Design for Manufacturing (DfM) We don’t design just for looks; we design for injection. From…

We produce high-end pill boxes, they are also screen printed by us. Combining practicality and aesthetics, our boxes offer an elegant solution for the daily organization of medications.

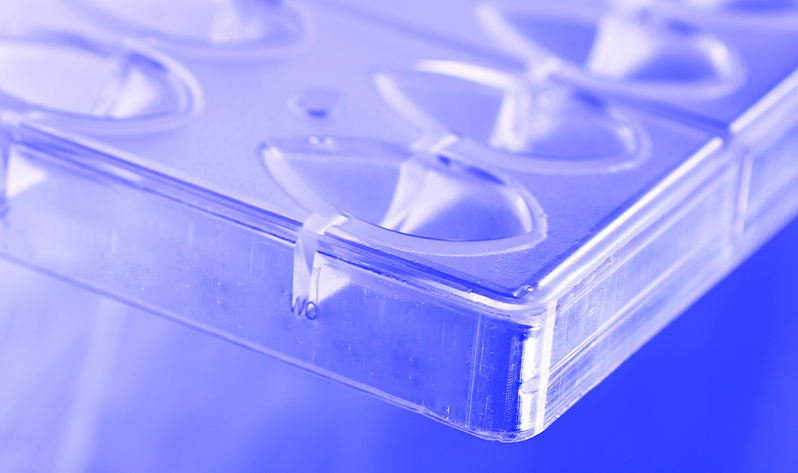

Are you looking for a chocolate Packaging Manufacturer in Belgium and France ?Moulding Injection also specialises in the production of chocolate packaging. Our design office is located in Belgium - the country of chocolate par excellence! - We have already produced a lot of chocolate packaging.What is our approach?We think first of all about the end customer; a box of chocolate must reflect the quality of the product, it must also be concerned with maintaining the quality of the product throughout…

Design, modelisation and production of polycarbonate shower.

Reinforced PA66 injection-moulded plastic ring, heat-resistant >150°.

Blow-moulded bottle and 10ML child-resistant caps (chemical-resistant)

Our project involved reverse-engineering a plastic handle for which we didn't have the original drawings. We used 3D scanning techniques to capture every detail, then produced a drawing.This enabled us to produce the plastic injection molded handle; identical to the initial model.

Manufacturing using silicone molds, also known as vacuum casting, is a popular technique for producing small series or quickly duplicating prototypes. This process begins with the creation of a master model, crafted using advanced technologies such as CNC machining, stereolithography (SLA), or selective laser sintering (SLS). Once the master model is ready, a precise mold is created by surrounding it with liquid silicone. This flexible and detailed mold is then used to faithfully replicate the original…

As an online company, we receive daily requests from injection mold manufacturers. We always use the same reference file to position the different mold manufacturers. Prices can vary from simple to triple, quadruple and even almost 10 times the price.Why use price comparison for plastic injection molds?Are you looking for plastic injection molds, but don't really know which manufacturer to turn to? In the plastics industry, there are a huge number of manufacturers of injection molds and plastic…

How did we go about it? We produced the tooling, i.e. the steel mold, in 6 weeks. The first samples of the display unit were then delivered to Julien for testing. After a few adjustments to the dimensions, the product was born.We chose polycarbonate for its production, as this plastic material is light yet has excellent resistance. MusiWall customers will have an easy-to-handle, rigid and transparent display that fits in with any style of home!As a manufacturer of plastic injection molds, we help…

Each customer has, by nature, a specific need and demand for its plastic part manufacturing. Moulding Injection's job is to reconcile these needs as well as possible, with all the technical requirements.Because the design of the plastic part, inseparable from the creation of the plastic mould, requires that all aspects be thought out well in advance, from manufacture to the final destination.The mould maker must then take into account the constraints specific to the plastics industry, such as…

What makes Moulding Injection's production quality unique is the combination of competitive advantages that few other industry players can claim. Indeed, beyond the quality of our showerheads produced in Europe (thanks to a strict respect of the standards imposed by the French ACS), it is really our management capabilities that make us suppliers you will want to keep. Our Minral Shower Head project here.The two key factors of standardisation of plastic injection quality in each of our production…

The main barrier to launching a new plastic product is often the initial tooling cost (CAPEX). For a startup or an innovative SME, spending €15,000 or €30,000 for a mold before selling the first part is a major risk. At Moulding Injection, we believe in the projects we support. That’s why we created a unique offer on the market: Co-Investment.The principle is simple If your project has solid technical and commercial potential (and ideally a positive societal or environmental impact), we are…

Plastic injection (or injection molding) is the standard industrial process for manufacturing polymer parts, from simple protective shells to high-safety automotive components.Unlike 3D printing, which builds material layer by layer, injection molding allows for the production of thousands of strictly identical parts in a few seconds.The 4-Step Cycle 1. Melting (Plasticizing) The raw material, in granule form (ABS, PP, PA6...), is poured into the hopper. It is heated and mixed by a screw until a…

Bioplastics are an alternative to thermoplastic materials from the fossil industry. Composed of vegetable carbon (obtained by processing corn starch, potato), bioplastics are biodegradable. These materials can be composted. These bioplastics are an alternative to ABS or Polycarbonate; they have the same mechanical properties (service life, hardness). The drawback is the limited heat resistance of these products. (For example, it is not recommended to use them for hot liquid cups.) Please feel free…

Supply security has once again become the top priority for manufacturers. It is likely that European authorities will favor these relocation processes in the coming months, either through subsidies to companies or through a political will for reindustrialization. However, economic reality is stubborn. Manufacturing a complex mold in Europe is expensive and takes time. Does this mean giving up on local production?The Trap: "All China" vs "All Europe" For years, the easy solution was to do everything…

Belgium is the country that spells chocolate, and connoisseurs across the world agree with the fact that Belgian chocolatiers have mastered the art of chocolate making, with such rich traditions and exquisite flavors. But that is only half of the story. It's also behind the satisfying making of delicacies because proper packaging of chocolate doesn't let it get stale as well as enhances its appeal. This blog is going to discuss the connection that exists between the chocolates packaged in…

For instance, accuracy and efficiency are key to manufacturing. The many critical processes companies depend on as they produce quality plastic parts include one specific one where things stand out, which is the so-called injection molding. Conceivably important, though, is the selection of a dependable injection molding manufacturer in seeking the right partnership. It goes further to discuss what aspects to consider when selecting an injection molding manufacturer, advantages one gets when working…

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown, so has the want for revolutionary and great molds. For chocolate makers, whether they are artisanal makers or huge extent manufacturers, a dependable source of high-quality equipment is important to growing their dream chocolate. One of the most vital equipment you could have inside the chocolate-making technique is a mold, which is where custom plastic chocolate molds come into play.While working…

Do you have a plastic part without its original blueprint? Do you need to improve a design or restart production based on an existing object?We offer a complete reverse engineering service to reproduce or optimize your industrial parts, even the most complex ones.The principle is simple: we scan your existing part in 3D with high precision to generate a faithful digital model. This model is then reworked in CAD (Computer-Aided Design) and optimized according to your technical or functional constraints.Why…

The fluidity between design and production is at the heart of our partnership with LGR Design Studio. Today, our partner design office takes a new technical step with the installation of a new production unit in the heart of the Belgian workshop.The Machine: 3-Axis CNC (Model 540)LGR has just commissioned a robust digital machining center (CNC) capable of precisely machining technical plastics, aluminum, and light alloys. 8-tool automatic changer: The machine switches from milling to drilling instantly,…