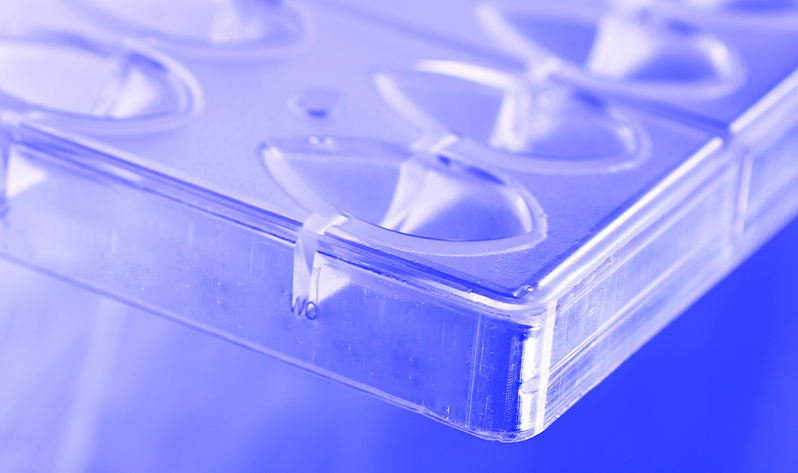

In modern automotive engineering, reliability is found in the details. Moving away from the race for size, we specialize in the injection molding of **precision components, connectors, and functional supports**.

Our infrastructure is scaled to produce small to medium-sized parts (from a few millimeters up to 20-30 cm), where tolerances are measured in hundredths and material quality is critical for the safety and durability of on-board systems.

For parts such as LCD screen brackets, sensor housings, or locking elements, there is no room for error. Our expertise focuses on strict adherence to the 3D file (“3D Data takes precedence”) and associated 2D drawings.

We guarantee compliance on critical points:

Small technical parts under the hood or behind the dashboard undergo intense thermal and vibratory stress. Unlike basic aesthetic parts, these functional components require an intact molecular structure.

We do not manufacture interior trim or large body panels. Our core expertise is focused on the "invisible" yet indispensable elements:

The production of small parts requires specific rigor. A drift of just a few microns in a multi-cavity mold can make an entire batch unusable.

We apply industry validation methods (PPAP / IS):

Looking for a partner for your precision components?

Send us your files (STEP/IGES). We will analyze the feasibility of your small technical parts and commit to meeting the tightest tolerances.

The fluidity between design and production is at the heart of our partnership with LGR Design Studio.…

Do you have a plastic part without its original blueprint? Do you need to improve a design or restart…

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…