In the medical and paramedical sectors, a plastic part is not just a simple component: it is often the guarantor of a device’s seal or a patient’s safety.

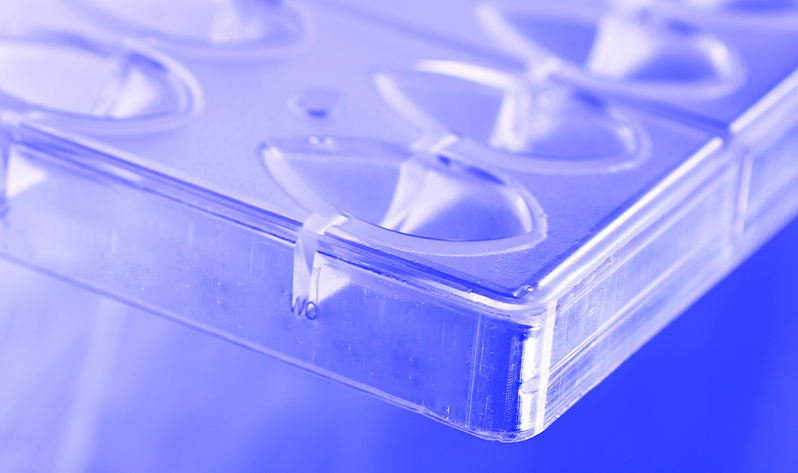

Our expertise focuses exclusively on the injection molding of small technical parts and tubular geometries. We support medical device manufacturers and laboratories in the production of components requiring absolute finesse and cleanliness.

The injection molding of “tube-like” parts (fittings, syringe bodies, cannulas, tips) presents technical challenges that few mold makers master perfectly. A minimal deviation of the central core and the part becomes unusable.

We guarantee:

We process polymers that meet the strict standards of pharmacopoeia. We ensure material segregation to avoid any cross-contamination.

Even without an ISO 7 certified cleanroom, we apply strict hygiene procedures inspired by GMP (Good Manufacturing Practices):

Our machine park is optimized for small-volume, high-tech parts:

Need to secure your consumable production?

The production of tubular parts cannot be improvised. Entrust us with your 3D plans for a rheological analysis focused on filling balance and concentricity.

The fluidity between design and production is at the heart of our partnership with LGR Design Studio.…

Do you have a plastic part without its original blueprint? Do you need to improve a design or restart…

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…