In a world of dwindling resources, the plastics industry is often singled out. At Moulding Injection, we refuse to accept this as a finality. We are convinced that plastic—when well-designed, durable, and recycled—remains an essential material for the future.

Our commitment to eco-responsibility is more than just a label. It is a profound transformation of our working methods, built on four fundamental pillars.

Responsibility begins at the drawing board. A poorly designed product becomes waste that is difficult to process. That is why our engineering department systematically integrates the product life cycle into its analyses:

Our factory has been optimized to reduce its energy impact and waste. We apply a strict "Zero Loss" policy internally:

All our production scraps (runners, purgings) are granulated directly at the machine and re-injected into the production cycle. Nothing is lost, everything is transformed. Furthermore, we invest in next-generation electric injection presses, which are much more energy-efficient than older hydraulic systems.

We support our clients in the transition toward more virtuous materials. We do not limit ourselves to standard fossil-based plastics:

This is often the forgotten argument: logistics. Importing a mold or parts from Asia generates a disastrous carbon footprint.

By producing in Belgium, in the heart of Europe, we drastically reduce the miles traveled by your products. Choosing Moulding Injection means choosing a local industry that respects the strictest environmental and social standards in the world (EU Standards).

Being eco-responsible doesn't mean stopping production. It means producing intelligently. It means ensuring that the part we manufacture today has real utility and a minimal impact on tomorrow.

The fluidity between design and production is at the heart of our partnership with LGR Design Studio.…

Do you have a plastic part without its original blueprint? Do you need to improve a design or restart…

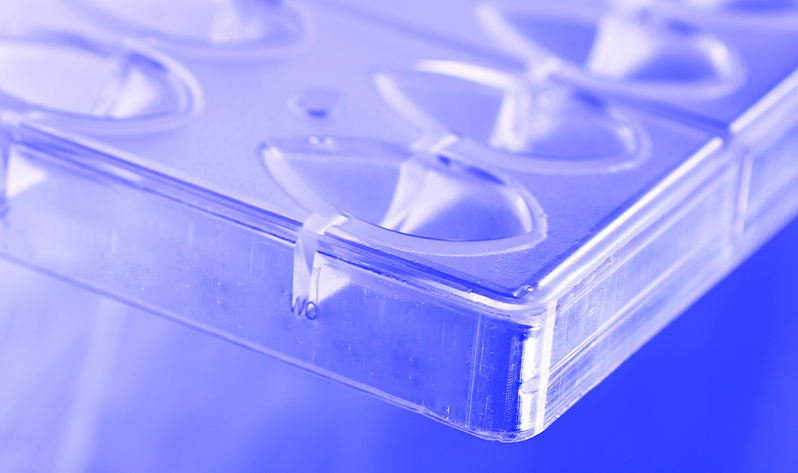

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…