In the high-end lighting sector, plastic must not only be functional, it must be beautiful. We produce trim and fastening components that meet the dual requirements of both designers and installers.

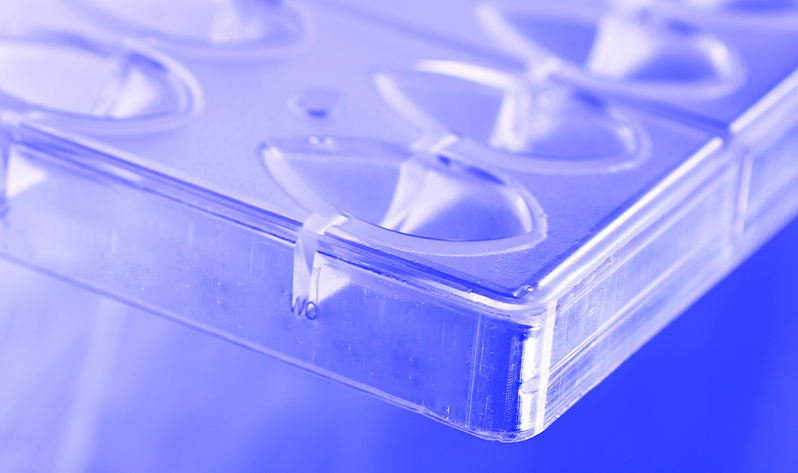

Our specialty? Revolution parts (rings, flanges, diffusers) integrating high-precision threading and uncompromising surface finishes.

Successfully molding a plastic thread on a thin ring is a technical challenge. A single flash or oval deformation and the part is unusable.

We master advanced molding techniques for these geometries:

On a lighting fixture, the retaining ring is often a visible part. It must present a look as high-quality as the glass or metal it accompanies.

The choice of material is crucial for long-term durability against the heat of the light source (LED or other) and for light diffusion.

We primarily work on structural and decorative elements:

Developing a new lighting range?

The quality of your finish depends on the quality of your molds. Send us your 3D files to validate thread feasibility and define the most cost-effective demolding strategy.

The fluidity between design and production is at the heart of our partnership with LGR Design Studio.…

Do you have a plastic part without its original blueprint? Do you need to improve a design or restart…

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…