Chocolate is a fragile and precious product that deserves a showcase worthy of its quality. We have developed a unique offer for artisan chocolatiers and industrial confectioners: complete management of your packaging.

No more juggling between a plastic supplier and a cardboard manufacturer. We design the "Blister + Box" duo to guarantee perfect dimensional compatibility and optimal protection for your creations during transport.

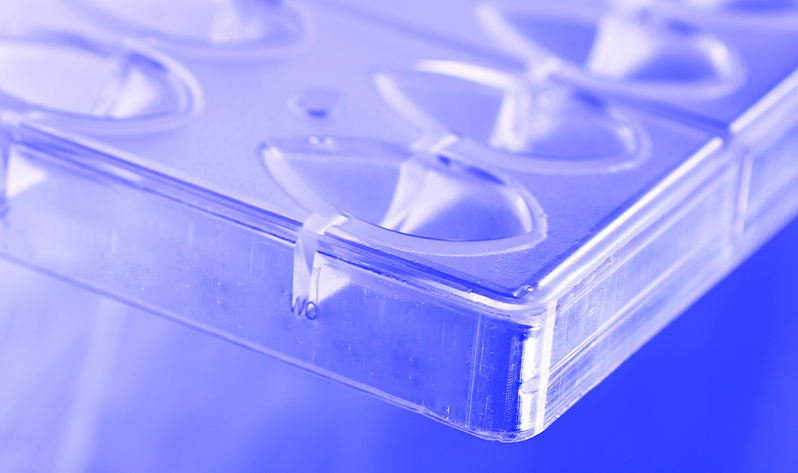

The interior tray has two functions: to immobilize the pralines to prevent breakage and to enhance them through the play of light. We produce custom cavities adapted to the exact shape of your molds.

We deliver the finished product. Your cardboard packaging is designed simultaneously with the blister for a millimeter-perfect fit (ensuring no "rattling" inside the box).

Working for the food industry requires strict standards. Our production chain follows HACCP principles to guarantee the absence of physical or chemical contamination.

Launching your Easter or Christmas collection?

Send us the dimensions of your chocolates or your 3D files. We will create a blank mockup (cardboard prototype + blister) to validate the volume and fit before production starts.

The fluidity between design and production is at the heart of our partnership with LGR Design Studio.…

Do you have a plastic part without its original blueprint? Do you need to improve a design or restart…

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…