When conventional thermoplastics reach their limits in terms of thermal resistance or flexibility, silicone is the answer. We master two distinct processes to meet all your needs, from single prototypes to mass production.

For serial production, high precision, and medical applications.

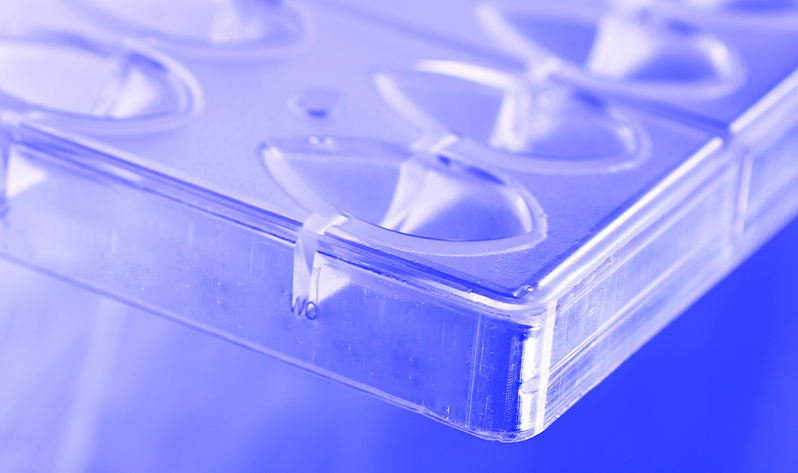

LSR (Liquid Silicone Rubber) injection is an industrial process using specialized presses to inject a two-component system under pressure into a heated mold. It is the ideal solution for high volumes requiring perfect repeatability.

For rapid prototyping and cost-effective small batches.

To validate a design or produce a few dozen parts without investing in expensive steel tooling, we use gravity casting.

We guarantee full traceability and the compliance of our materials with the strictest European directives:

Not sure which technology to choose?

Let us know your required quantity and the part's application (sealing, food contact, heat resistance). We will guide you toward the most cost-effective process.

The fluidity between design and production is at the heart of our partnership with LGR Design Studio.…

Do you have a plastic part without its original blueprint? Do you need to improve a design or restart…

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…