By ADMIN

The fluidity between design and production is at the heart of our partnership with LGR Design Studio. Today, our partner design office takes a new technical step with the installation of a new production unit in the heart of the Belgian workshop.

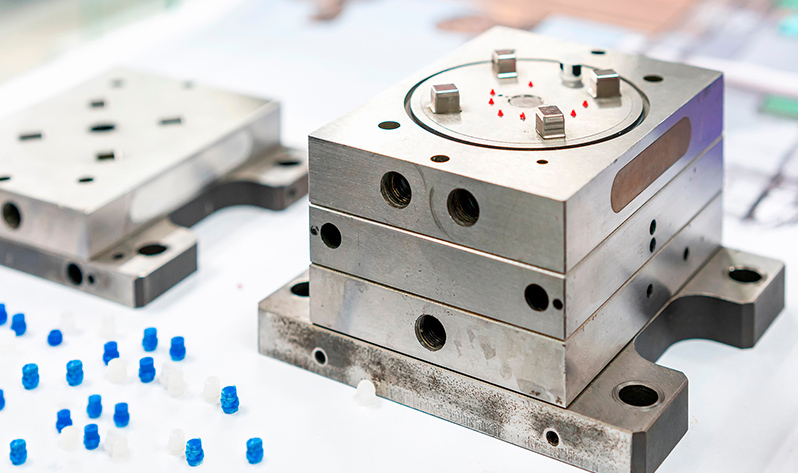

LGR has just commissioned a robust digital machining center (CNC) capable of precisely machining technical plastics, aluminum, and light alloys.

Word from the team:

"This investment confirms our desire to master the value chain locally. From the 3D file to the machined part, everything is done here for maximum responsiveness."

Having this machine "in-house" in Belgium drastically reduces development times. We no longer depend on subcontractors for urgent mechanical operations.

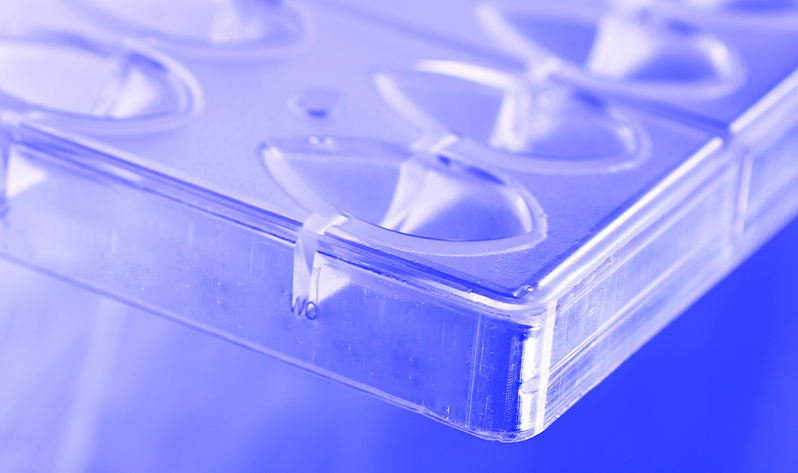

Before injecting, we can now machine functional prototypes directly from the block (ABS, POM, PA6), offering mechanical resistance far superior to classic 3D printing.

LGR can quickly manufacture the assembly fixtures or inspection jigs that Moulding Injection needs to assemble your parts in series.

An insert to retouch? An engraving to add?

Thanks to this CNC, we can perform quick modifications on small molds or aluminum cavities without sending the tooling back to a heavy factory. Precious time saved for your Time-to-Market.

Do you have a plastic part without its original blueprint? Do you need to improve a design or restart…

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…

For instance, accuracy and efficiency are key to manufacturing. The many critical processes companies…