The gap between "Design" and "Factory" is the #1 cause of industrial project failure. We have eliminated it.

Too many projects (Startups, IoT, Medical) waste months going back and forth between an external design bureau (unaware of machine constraints) and a mold maker.

At Moulding Injection, we have integrated engineering directly into the factory heart through our exclusive partner, LGR Design Studio.

We don’t design just for looks; we design for injection. From the very first sketch, we integrate:

3D printing is a visual tool, not a functional one. To validate a clip or a hinge, you need the "real material."

Thanks to our in-house machining center, we carve your prototypes directly from the block (ABS, POM, PA6). You get a part with real mechanical properties in 3 to 5 days.

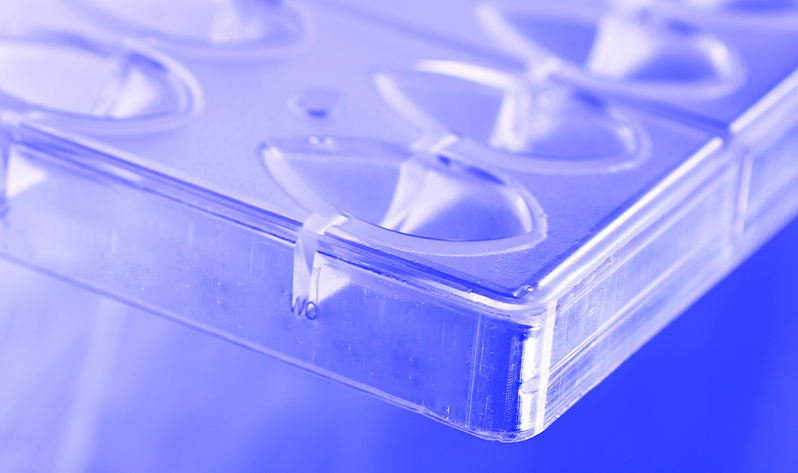

Need 200 parts? We produce pilot molds in aluminum. Fast (2-3 weeks) and cost-effective, they allow you to validate the injection process before investing in the steel serial mold.

The fluidity between design and production is at the heart of our partnership with LGR Design Studio.…

Do you have a plastic part without its original blueprint? Do you need to improve a design or restart…

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…