In interior design and architecture, the weight and cost of natural materials (solid wood, hewn stone, traditional plaster) are often major obstacles. Polyurethane (PU) offers the perfect solution: a complete visual illusion combined with unparalleled ease of installation.

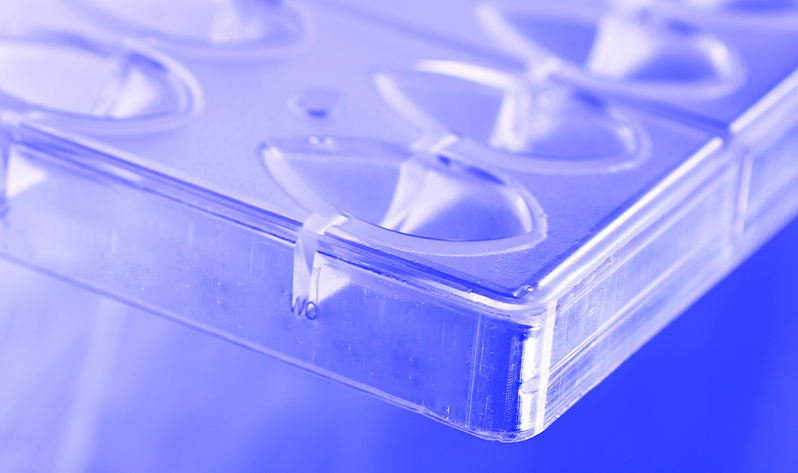

We produce structural or decorative elements using the injection or casting of rigid PU foams, capable of reproducing the finest texture details.

Thanks to our silicone or resin molds taken from real-life models, PU captures every wood grain and every stone pore with precision.

The choice of polyurethane is not just aesthetic; it is a pragmatic solution for work sites:

Depending on your volumes and part complexity, we adapt the technique:

Are you a decoration brand or an architect?

Create your own exclusive range of moldings. We can duplicate your hand-carved models for mass production. Contact us for a mold study.

The fluidity between design and production is at the heart of our partnership with LGR Design Studio.…

Do you have a plastic part without its original blueprint? Do you need to improve a design or restart…

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…