By ADMIN

Do you have a plastic part without its original blueprint? Do you need to improve a design or restart production based on an existing object?

We offer a complete reverse engineering service to reproduce or optimize your industrial parts, even the most complex ones.

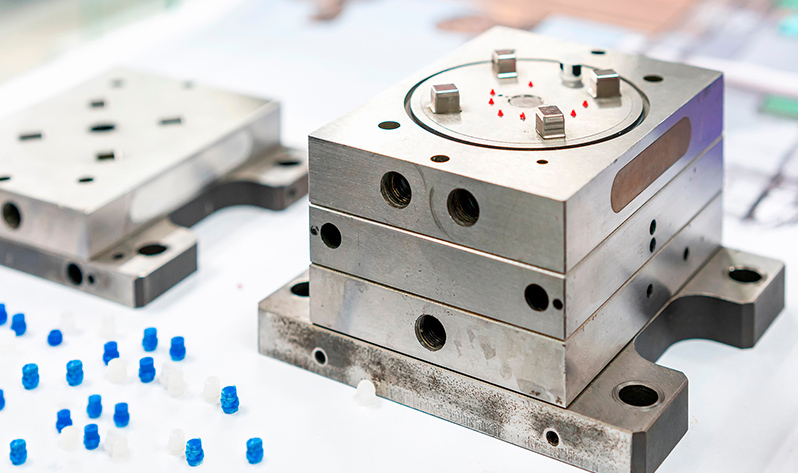

The principle is simple: we scan your existing part in 3D with high precision to generate a faithful digital model. This model is then reworked in CAD (Computer-Aided Design) and optimized according to your technical or functional constraints.

In the life of a factory, it frequently happens that a production line is blocked by the absence of a simple plastic component.

Faced with this, Reverse Engineering allows you to start from a "digital blank slate" using the physical part as the single source of truth.

Many think that simply "scanning" is enough to get a perfect part. This is false. A scan captures the object "as is," including its defects. To get an industrial part, we must reconstruct it.

We use structured light or laser scanners.

The result: A "point cloud" of the part. It is a digital fingerprint accurate to the micron, but it also contains the defects of the used part (scratches, warping).

This is where our expertise comes in. We redraw the part by converting the point cloud into perfect mathematical surfaces.

Smart Correction: If your model part is bent, we don't copy the defect. We reconstruct the perfect theoretical geometry so that the new part is fully functional.

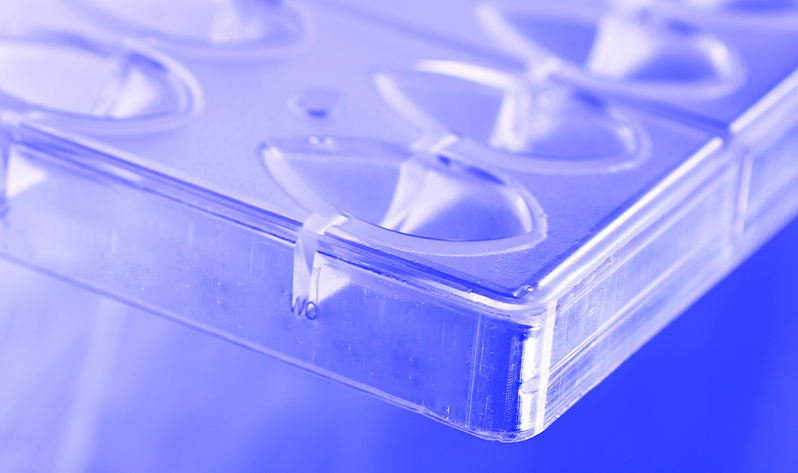

Once the reconstruction is validated, we deliver the 3D files (.STEP) and 2D drawings. These files are ready to launch the manufacturing of a new mould or for machining.

The fluidity between design and production is at the heart of our partnership with LGR Design Studio.…

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…

For instance, accuracy and efficiency are key to manufacturing. The many critical processes companies…