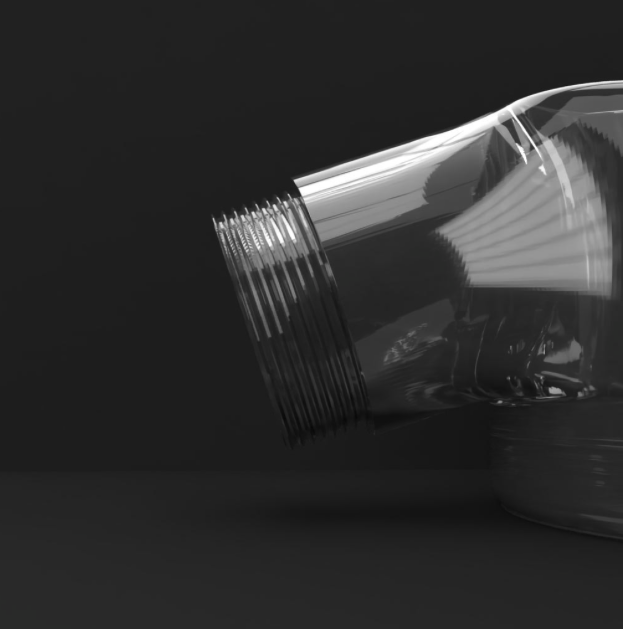

Manufacture of anti-limestone showerheads with health-compliant ratings

2020

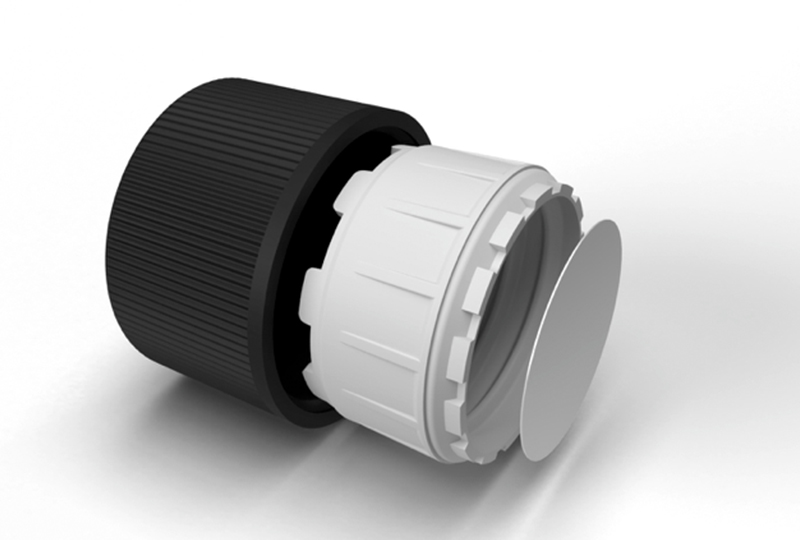

Manufacture of anti-limestone showerheads with health-compliant ratings

Our first priority is to add value to our customers' businesses by offering them only high-quality anti-scale showerheads. This, in turn, enables them to market robust, impeccable merchandise, convey a good corporate image, demonstrate their seriousness and develop sales and turnover.

To achieve this, and to ensure the reliability of the products we put on the market, our teams of professionals work closely with top designers and engineers to develop molds for the manufacture of anti-scale showerheads by plastic injection molding. Assisted by state-of-the-art tools, they handle all stages of production, from design to final part, and can produce large quantities.

OTHER PROJECTS

small-scale production using silicone molds

Manufacturing using silicone molds, also known as vacuum casting, is a popular technique for producing…

High-Quality 3D Prototypes

We create 3D-printed prototypes with a high-quality finish, enabling precise visualization of the final…

Production of a handle by reverse engineering

Our project involved reverse-engineering a plastic handle for which we didn't have the original…

Casting silicone

We specialize in two-component gravitational silicone production, offering custom molds and silicone…

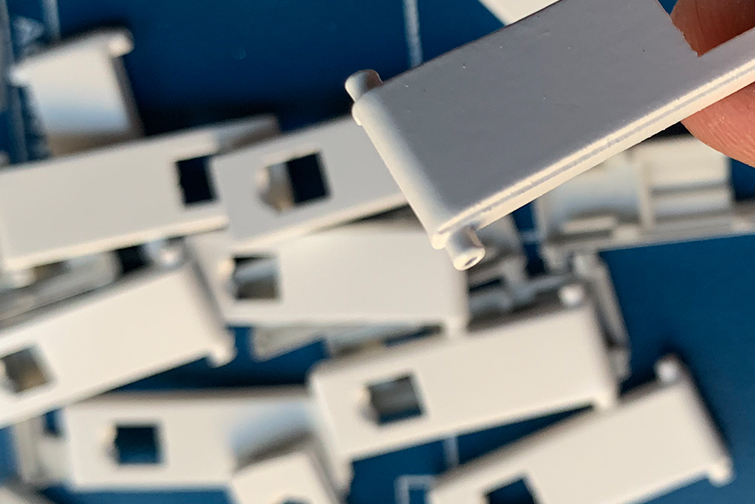

Creation of prototypes made in ABS cast in a mould with silicone.

Creation of prototypes made in ABS cast in a mould with silicone.

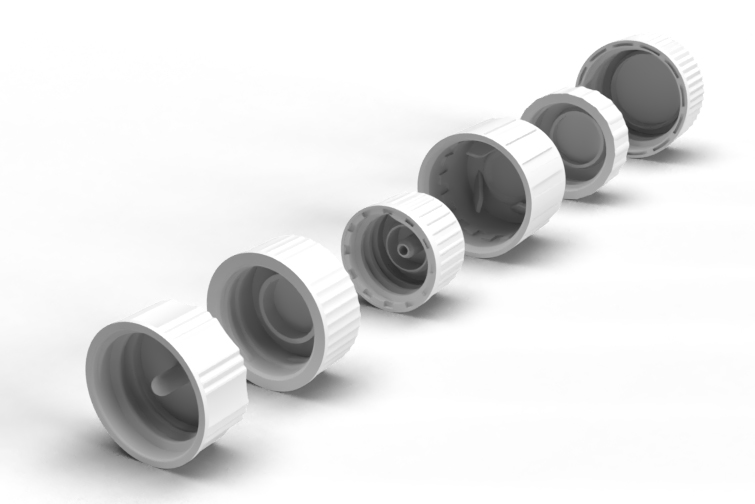

injection moulding caps DIN 18 DIN 20 DIN 22

We have moulds for injection moulding caps: DIN 18 DIN 20 DIN 22. We have also developed two moulds…

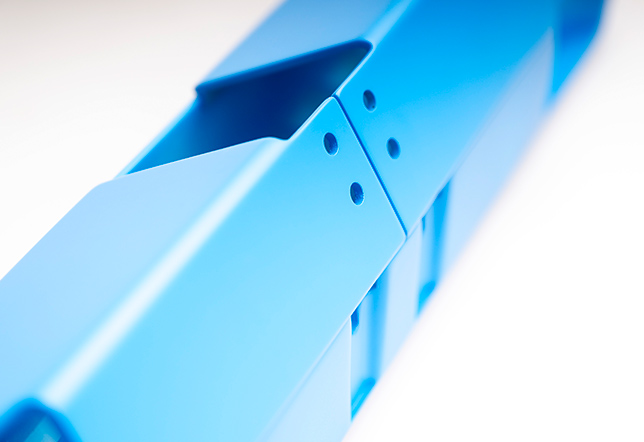

Plastic ring for lighting system

Reinforced PA66 injection-moulded plastic ring, heat-resistant >150°.

7 Chakras Shower – Polycarbonate Showers

Design, modelisation and production of polycarbonate shower.

Child safety closures (CRC)

We inject and finish our own Child Resistant Caps (CRC) in-house. We have developed specific molds for…

Mineral Shower Head

Mineral Shower HeadSanitary fittings 100% Made in Europe.Our shower heads are designed in Europe. Manufactured…

Frisbee plastic injection

Production of frisbees made from polypropylene (PP) or recycled ocean polypropylene (RPP). These sustainable…

Chocolate packaging and blister

Are you looking for a chocolate Packaging Manufacturer in Belgium and France ?Moulding Injection also…

Injection molding of pill boxes for pharmacies and para-pharmacies.

We produce high-end pill boxes, they are also screen printed by us. Combining practicality and aesthetics,…

Musiwall

Julien Paeschen, founder of MusiWall, called on our services to help him realize his ambition: to showcase…

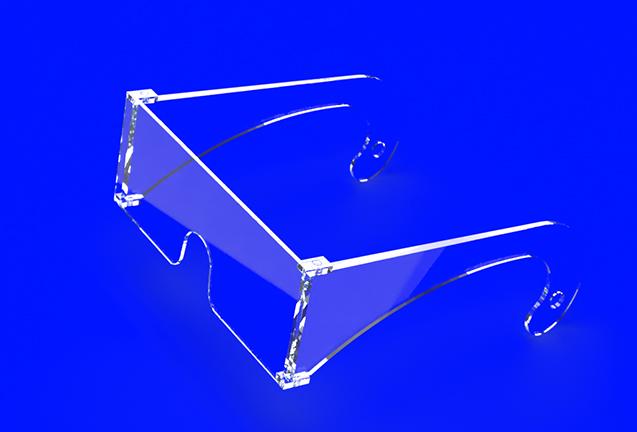

Injection molds for Polycarbonate goggles

We produced two injection molds for the injection of polycarbonate goggles used to protect hospital…