Do you have a product idea but no 3D file? Are you looking for a design that is both aesthetic and ready for industrial production?Because the crafts of mold making and design are complementary, we have established a close partnership with LGR Design Studio. Together, we offer you a turnkey solution: design creativity combined with the rigor of plastic injection molding.Who is LGR Design Studio?Specializing in industrial design and product development, LGR Design Studio supports inventors and companies…

The gap between "Design" and "Factory" is the #1 cause of industrial project failure. We have eliminated it. Too many projects (Startups, IoT, Medical) waste months going back and forth between an external design bureau (unaware of machine constraints) and a mold maker. At Moulding Injection, we have integrated engineering directly into the factory heart through our exclusive partner, LGR Design Studio.1. Design for Manufacturing (DfM) We don’t design just for looks; we design for injection. From…

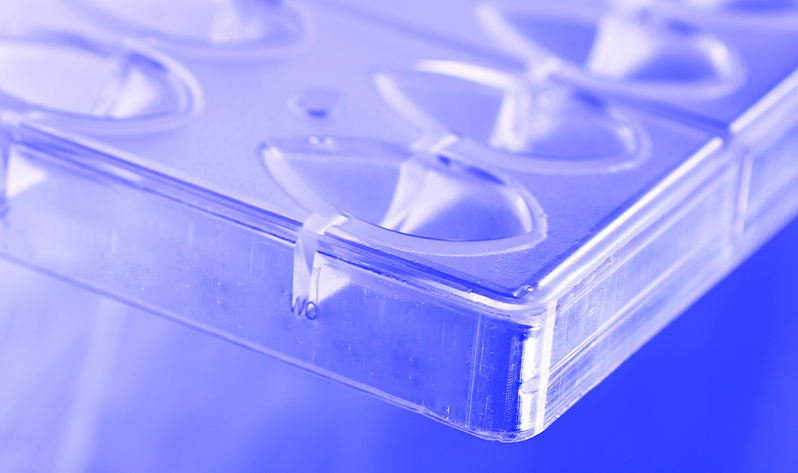

Manufacturing using silicone molds, also known as vacuum casting, is a popular technique for producing small series or quickly duplicating prototypes. This process begins with the creation of a master model, crafted using advanced technologies such as CNC machining, stereolithography (SLA), or selective laser sintering (SLS). Once the master model is ready, a precise mold is created by surrounding it with liquid silicone. This flexible and detailed mold is then used to faithfully replicate the original…

The fluidity between design and production is at the heart of our partnership with LGR Design Studio. Today, our partner design office takes a new technical step with the installation of a new production unit in the heart of the Belgian workshop.The Machine: 3-Axis CNC (Model 540)LGR has just commissioned a robust digital machining center (CNC) capable of precisely machining technical plastics, aluminum, and light alloys. 8-tool automatic changer: The machine switches from milling to drilling instantly,…