Do you have a product idea but no 3D file? Are you looking for a design that is both aesthetic and ready for industrial production?

Because the crafts of mold making and design are complementary, we have established a close partnership with LGR Design Studio. Together, we offer you a turnkey solution: design creativity combined with the rigor of plastic injection molding.

Specializing in industrial design and product development, LGR Design Studio supports inventors and companies in bringing their concepts to life.

Their strength? A "Design for Manufacturing" (DFM) approach. Unlike a purely artistic designer, LGR designs your parts by integrating our molding constraints from the very beginning (draft angles, parting lines, uniform wall thicknesses).

Visit the LGR Design Studio website →We simplify your development journey by coordinating design and manufacturing.

LGR transforms your sketch or idea into strong visual concepts. They focus on form exploration, ergonomics, and visual identity to ensure your product stands out on the market.

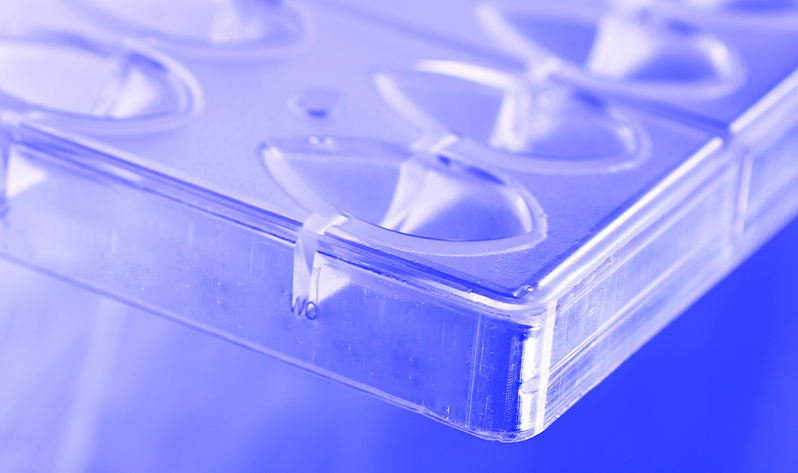

Creation of production-ready technical files (STEP/IGES). This is where the magic happens: parts are designed specifically for molding, with proper snap-fits and assembly systems integrated from the start.

Moulding Injection takes over the validated files. Since they are already DFM-optimized, we can launch the mold design phase immediately, avoiding costly back-and-forth corrective loops.

This is no longer an obstacle. Contact us, and we will put you in direct contact with the LGR team to start your study.

The fluidity between design and production is at the heart of our partnership with LGR Design Studio.…

Do you have a plastic part without its original blueprint? Do you need to improve a design or restart…

Chocolate has been a popular treat for loads of years, and because the chocolate enterprise has grown,…

Belgium has gained worldwide recognition for quality chocolate, which represents a combination of culinary…